FIA / FIU

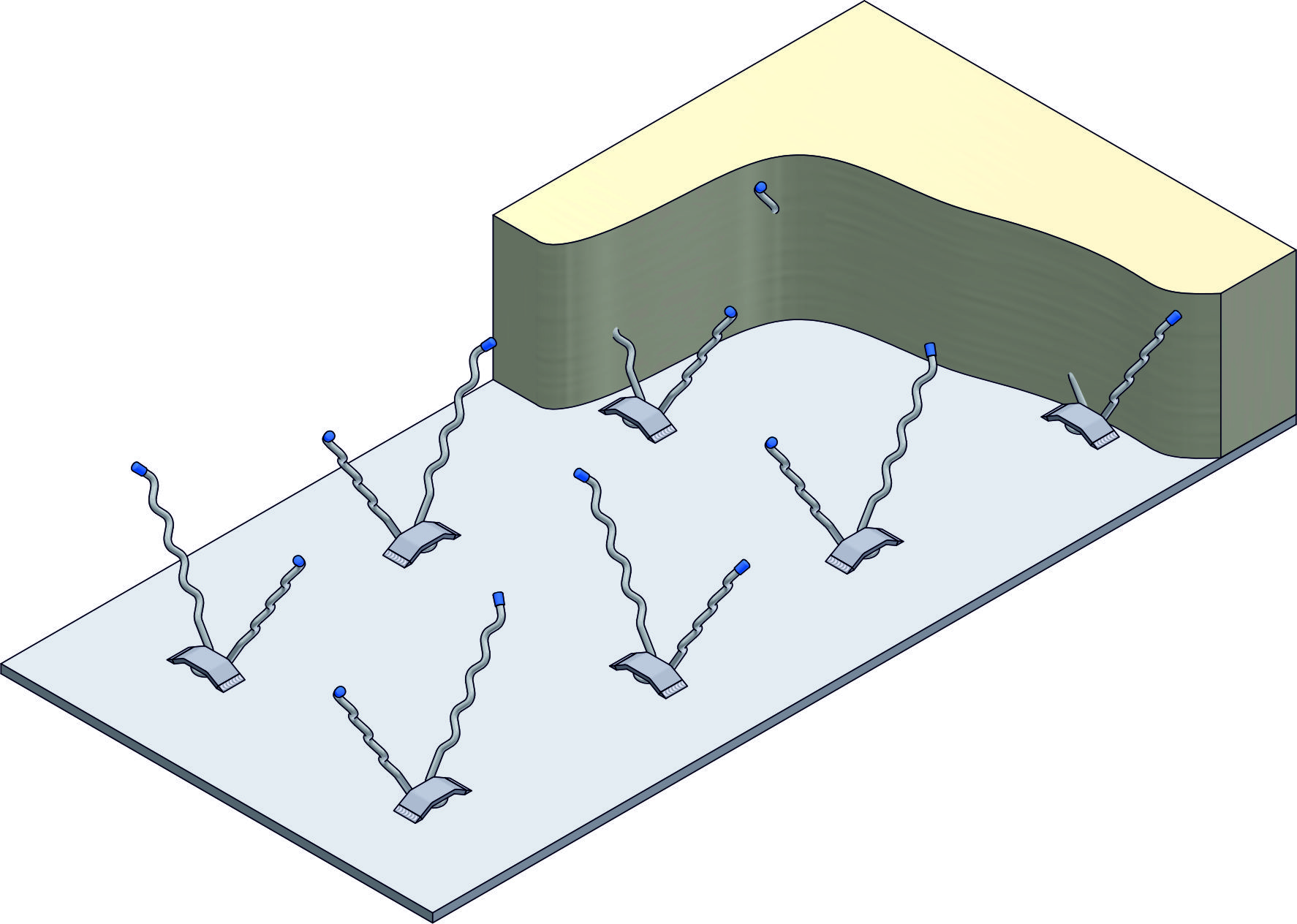

For refractory applications where it can be expected that the lining will be replaced regularly, so that there is rarely a situation where the refractory concrete wears out completely down to the steel casing, it is worthwhile using anchoring that is mounted with a reusable retention system.

The FI-System has been developed for this type of installation and consists of a lug and the FI anchor. The lug is generally made of carbon steel, therefore the same kind as the connection to the steel casing of the system component. Of course the lug can also be made from other materials depending on the situation.

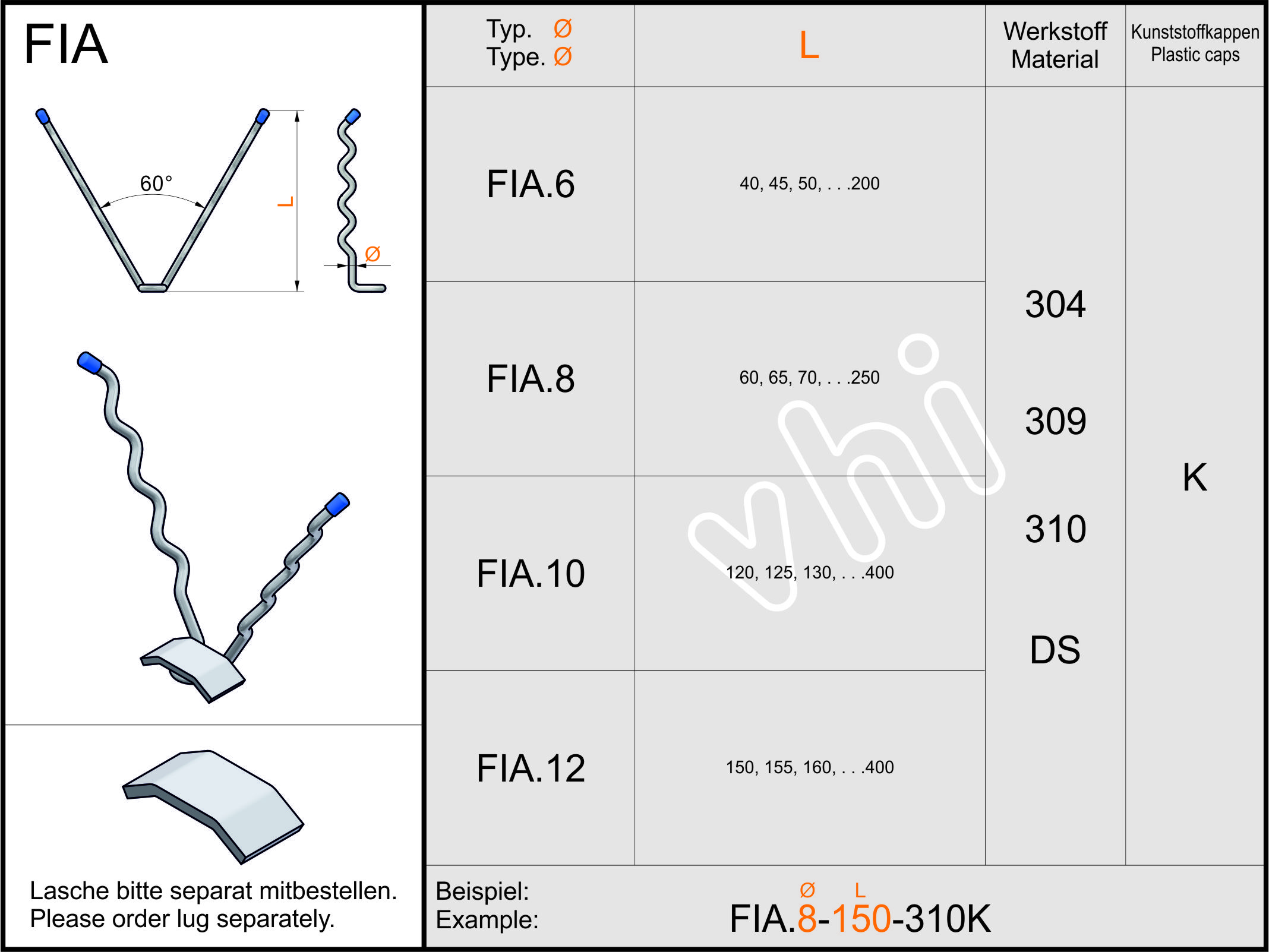

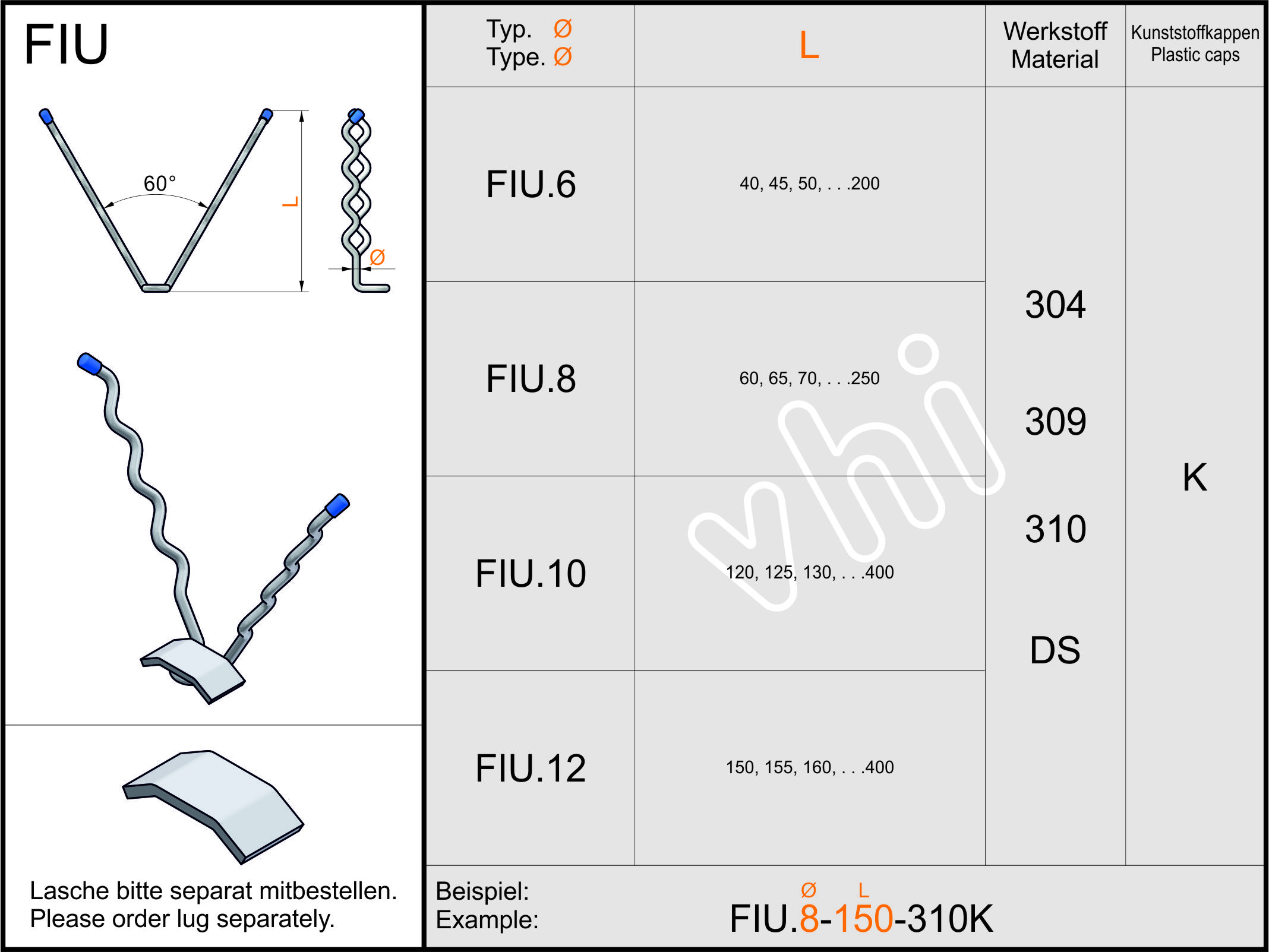

The FI-anchor, which has an angle of spread of 60° as standard, is supplied in diameters of 6 mm, 8 mm, 10 mm and 12 mm.

The correspondingly formed base of the FI-anchor is inserted into the lug that is welded onto the steel casing of the plant component. In the case of new lining, the residual refractory concrete is removed along with the old FI-anchors, new FI-anchors are inserted into the lugs and the new refractory concrete lining is put in place.

FI-anchors are very suitable for single layer linings but with gunned insulation layers are also ideal for multilayer linings.

Additional information

| APPLICATION | Roof, side wall, bottom |

|---|---|

| ATTACHMENT | Manual welding |

| REFRACTORY LINING | Mixes |

| INSTALLATION | Restoring |

| POSITION | immovable |

| TEMPERATURE | <1250°C |

| PROCESSING (CONCRETE) | Gießen, Spritzen |

| WALL CONSTRUCTION | Einschichtig, Mehrschichtig, Isolierung gespritzt |