Steel fibres

The homogeneity and convenient processing characteristics of monolithic (unshaped) refractories are ideal for refractory lining constructions. Unfortunately, such materials can only tolerate low tensile stresses and as we are aware refractory linings are subject to extreme variations of temperatures resulting in high stress levels.

ln many instances these resulting stress levels lead to lower than ideal refractory performance, frequent repair shutdowns thus lowering production capacity and higher costs. vhi steel fibres, when added to the refractory at 2 - 5 % by weight, provide improved properties of refractory linings.

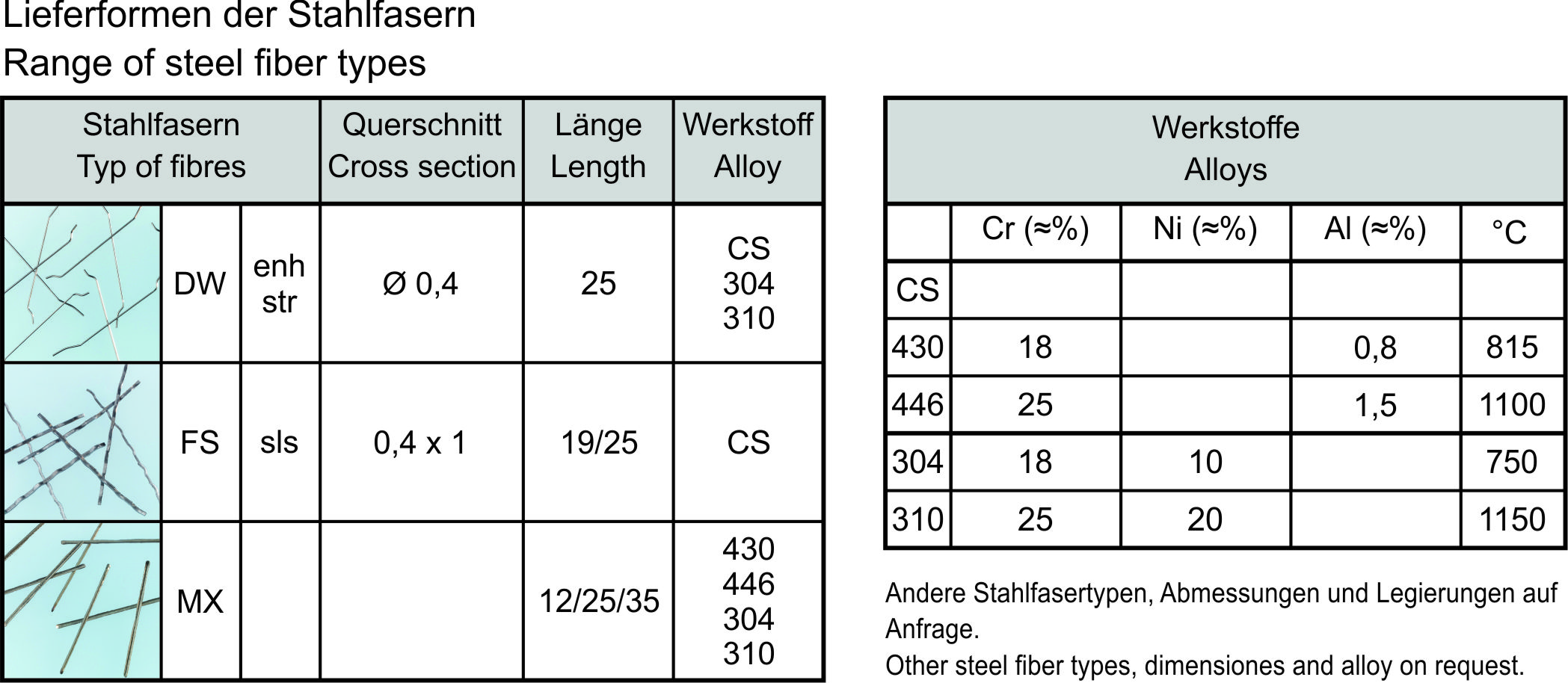

vhi steel fibres are available via three production sources:

- Wire - Type DW

- Strip - Type FS

- Metal Extract - Type MX

The fibres are available in various lengths, typically 25mm and various steel grades. So, they can accommodate the various temperature and corrosion resistant requirements.

Being homogeneously distributed within the refractory mass steel fibres accommodate tensile stresses resulting in improved resistance to thermal shock, act as crack arresters, bridge together fractured sections and minimise spalling of the refractory sections.

vhi steel fibres markedly extend the service life of refractory linings compared to those without fibres. They provide longer campaigns, increased production availability, reduction in operating costs and improved efficiency.

Here are the benefits at a glance:

- Improved resistance to thermal shocks

- Crack limitation

- Improved resistance to stresses

- Lower susceptibility to spalling

- Improved load bearing capacity