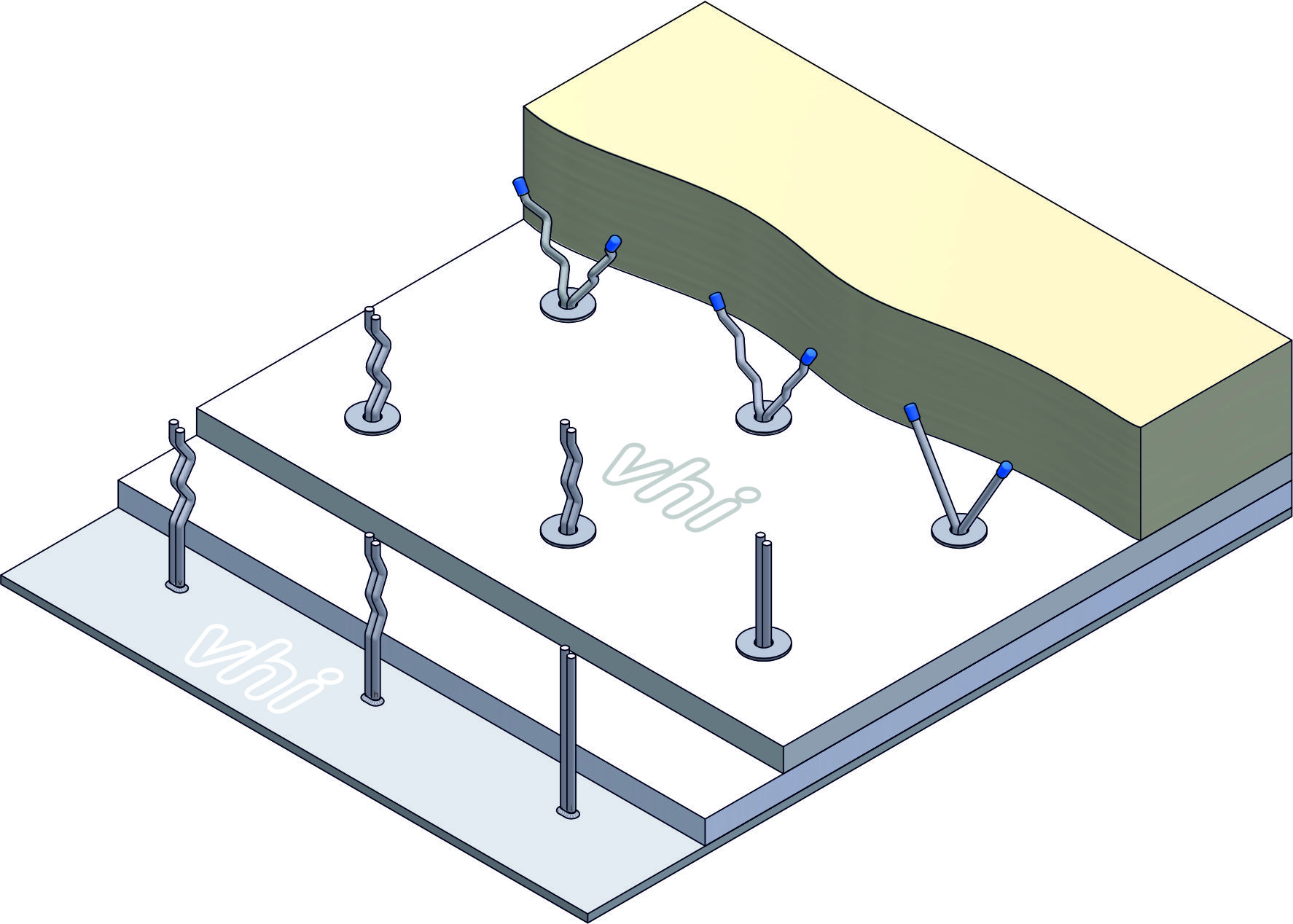

TWIN PIN-P

With the Twin-Pin Series, vhi provides an anchoring system that only spread once the insulation has been installed. As a result the adjustment work on the block insulation is minimized. Once the insulation has been put into position, the supplied washer is pushed over the anchor arms and the ends of the anchor are bent apart using two pipes. To make work easier, the two ends of the anchor are of different lengths. The washer is the abutment for this operation and also presses the block insulation against the substructure.

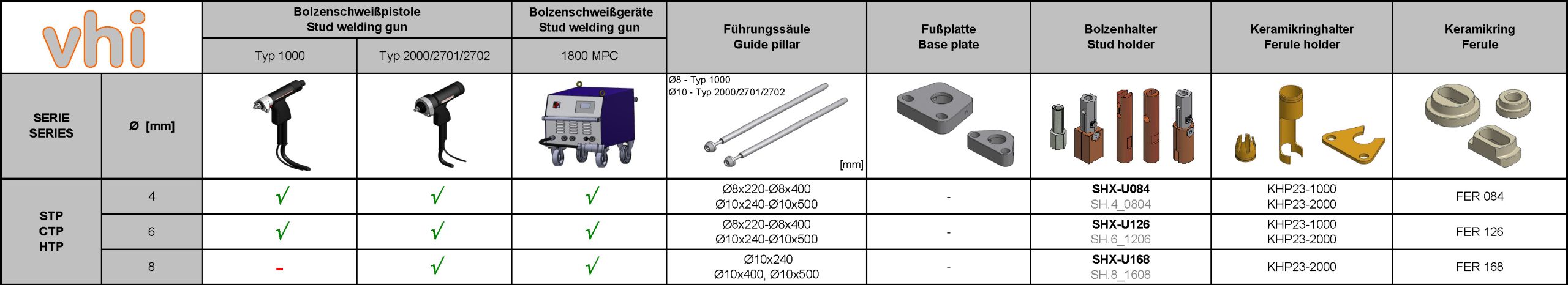

Type P of the Twin-Pin Series is designed for mounting using the stud welding process. It is therefore delivered with a ceramic ferrule as standard and aluminised on the welding tip if wished.

vhi supplies the Twin-Pin P Series in three versions:

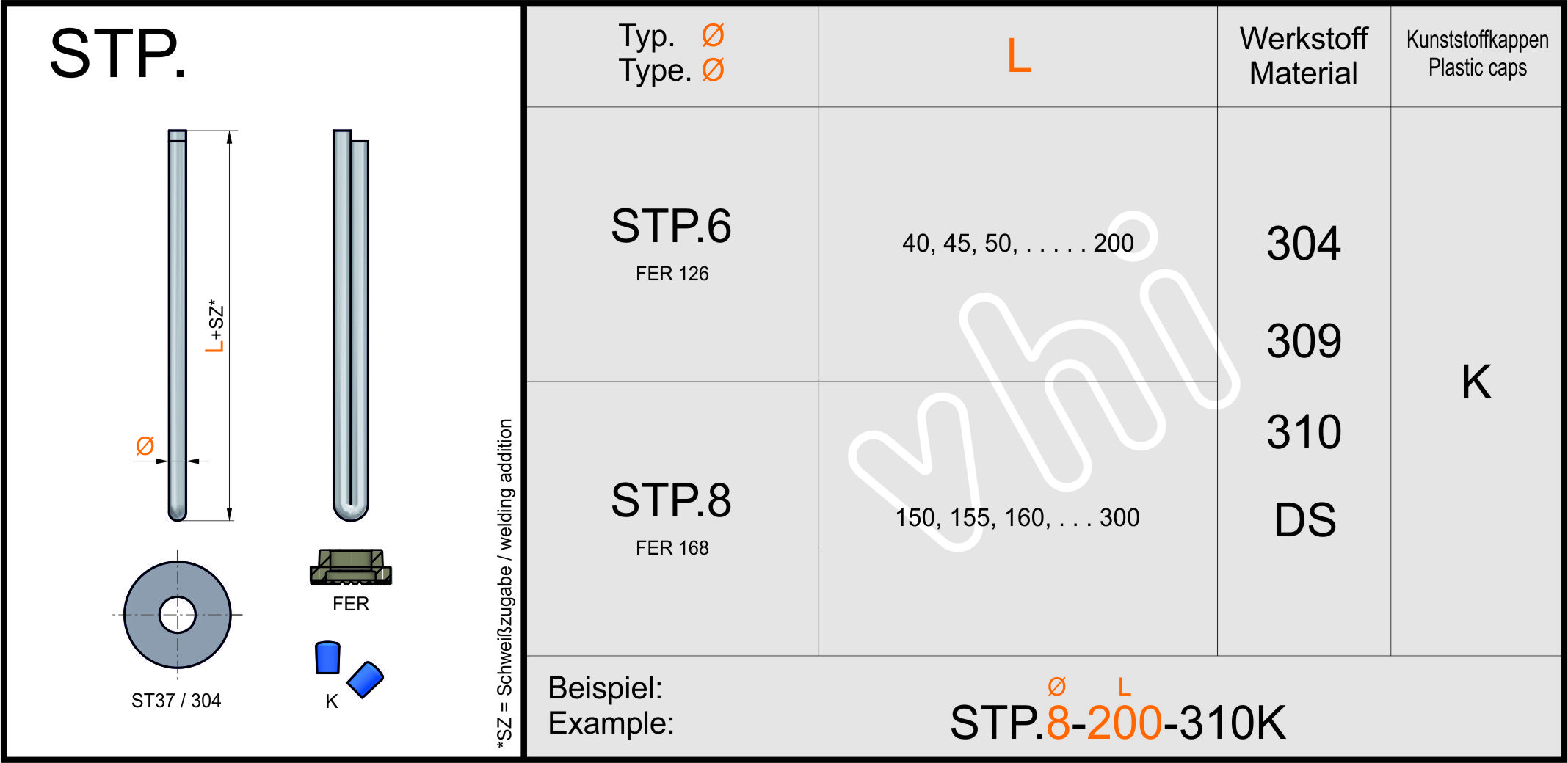

STP

Anchor without corrugation that can be used for simple anchoring tasks, such as for low wall thicknesses or in tub positions.

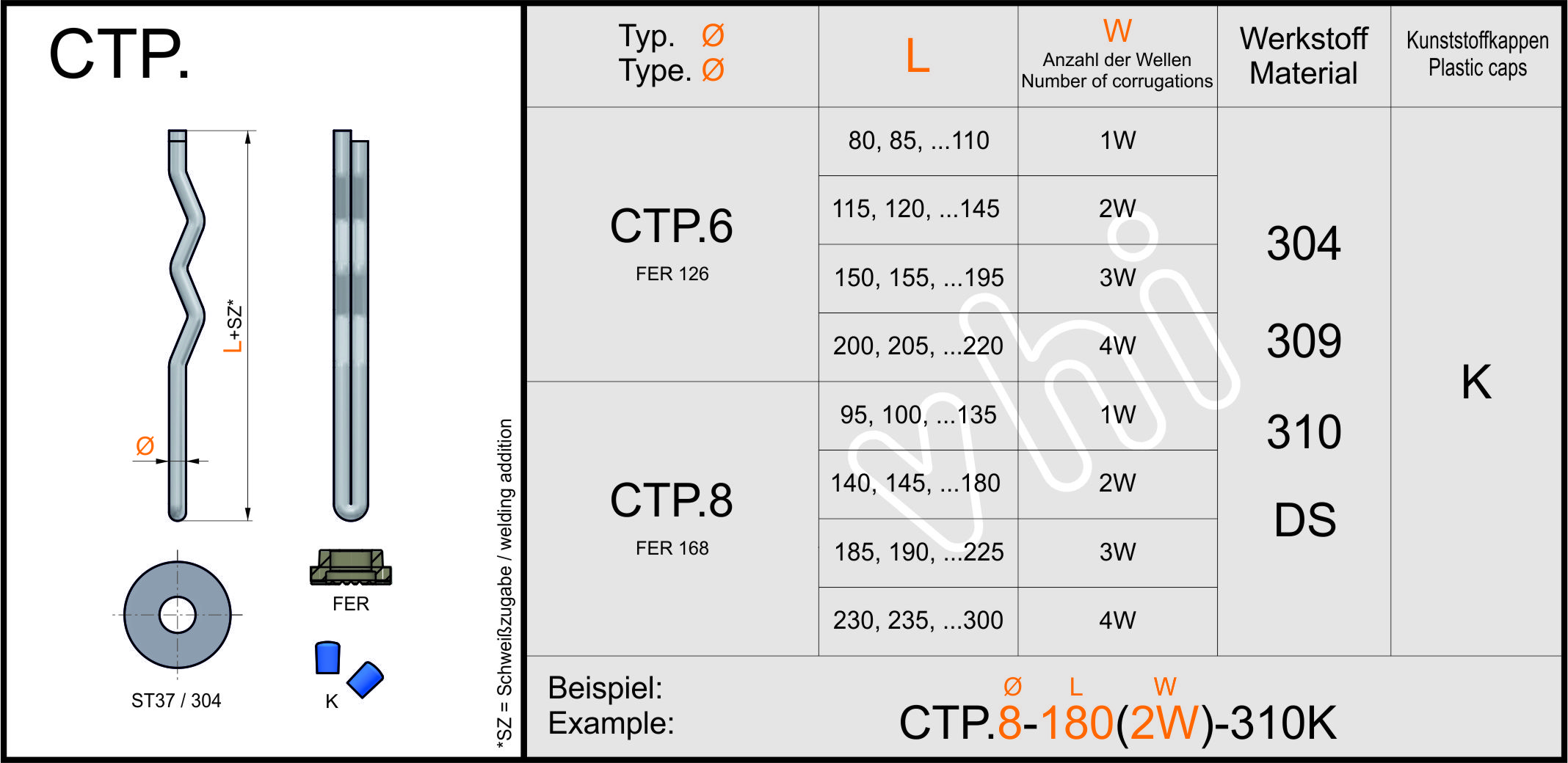

CTP

Corrugated anchor for average to difficult applications; the depth of the corrugation basically corresponds to the single diameter of the wire so that there is good transmission of the retention forces to the refractory concrete.

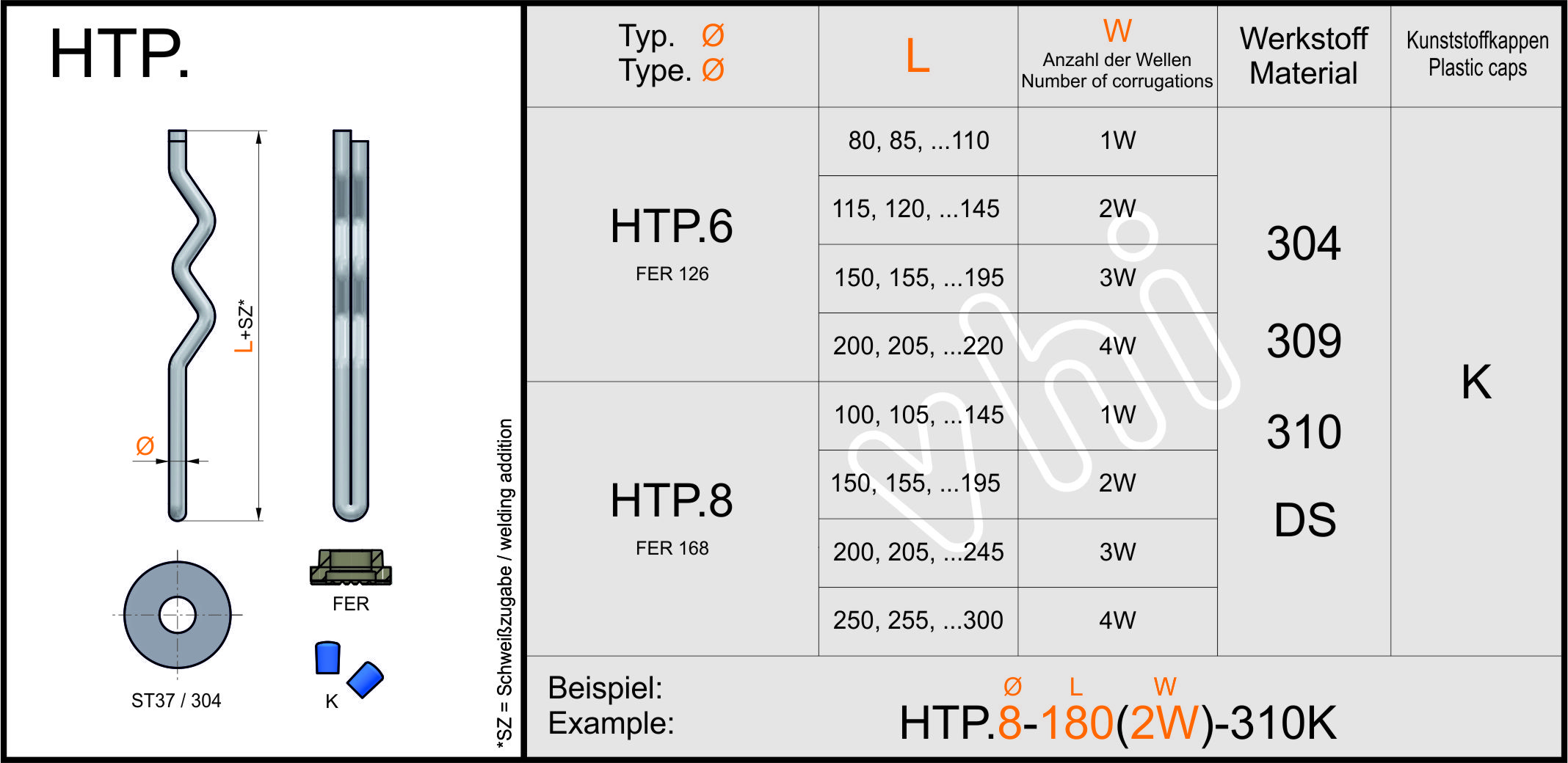

HTP

This type of anchor has a more pronounced corrugation. This produces yet better transmission of the retention forces to the refractory concrete.

Additional information

| APPLICATION | Roof, side wall, bottom |

|---|---|

| REFRACTORY LINING | Mixes |

| INSTALLATION | Bending |

| POSITION | immovable |

| TEMPERATURE | <1250°C |

| PROCESSING (CONCRETE) | Gießen, Spritzen |

| WALL CONSTRUCTION | Multilayer |

| ATTACHMENT | Stud Welding |