VB

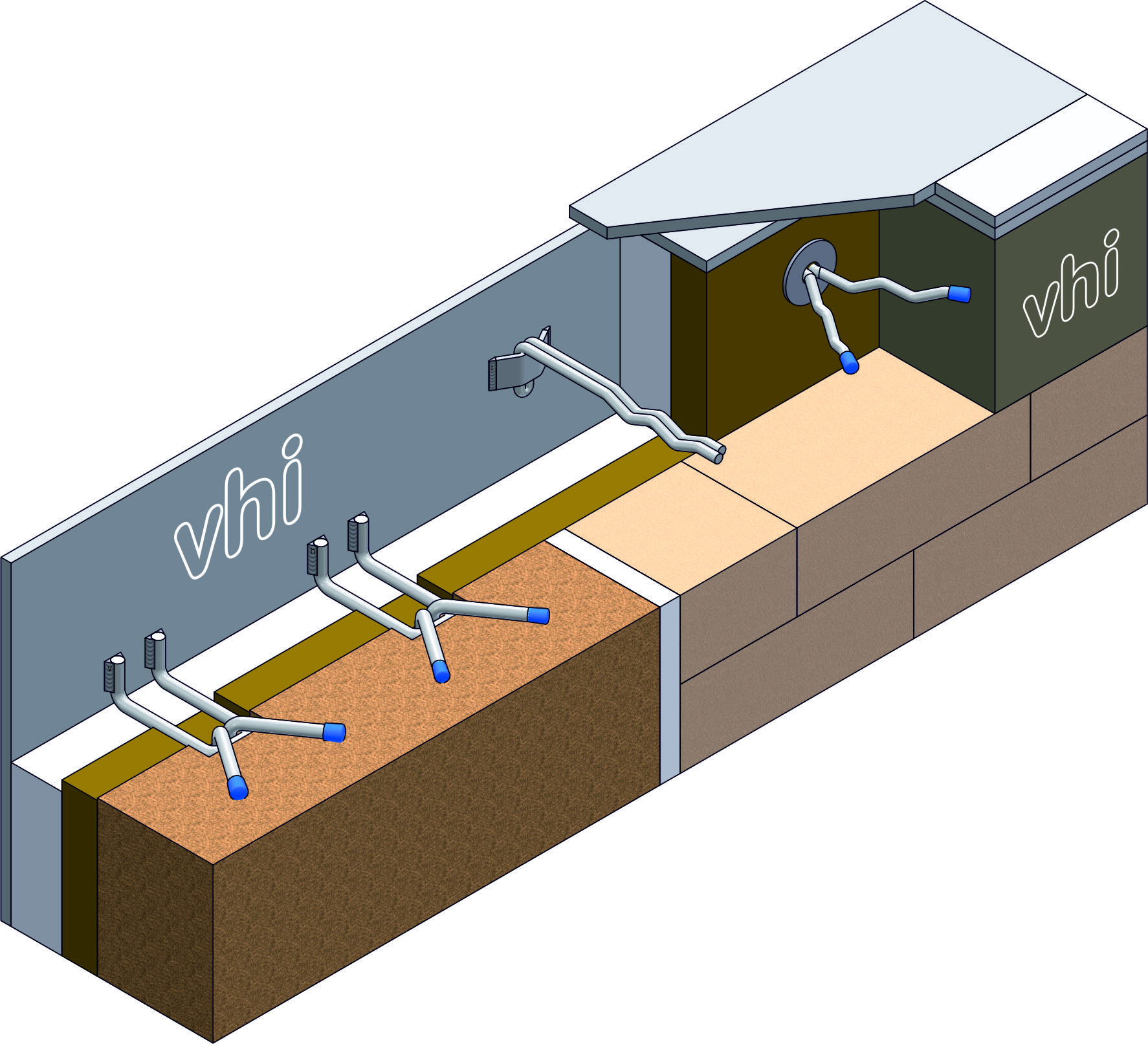

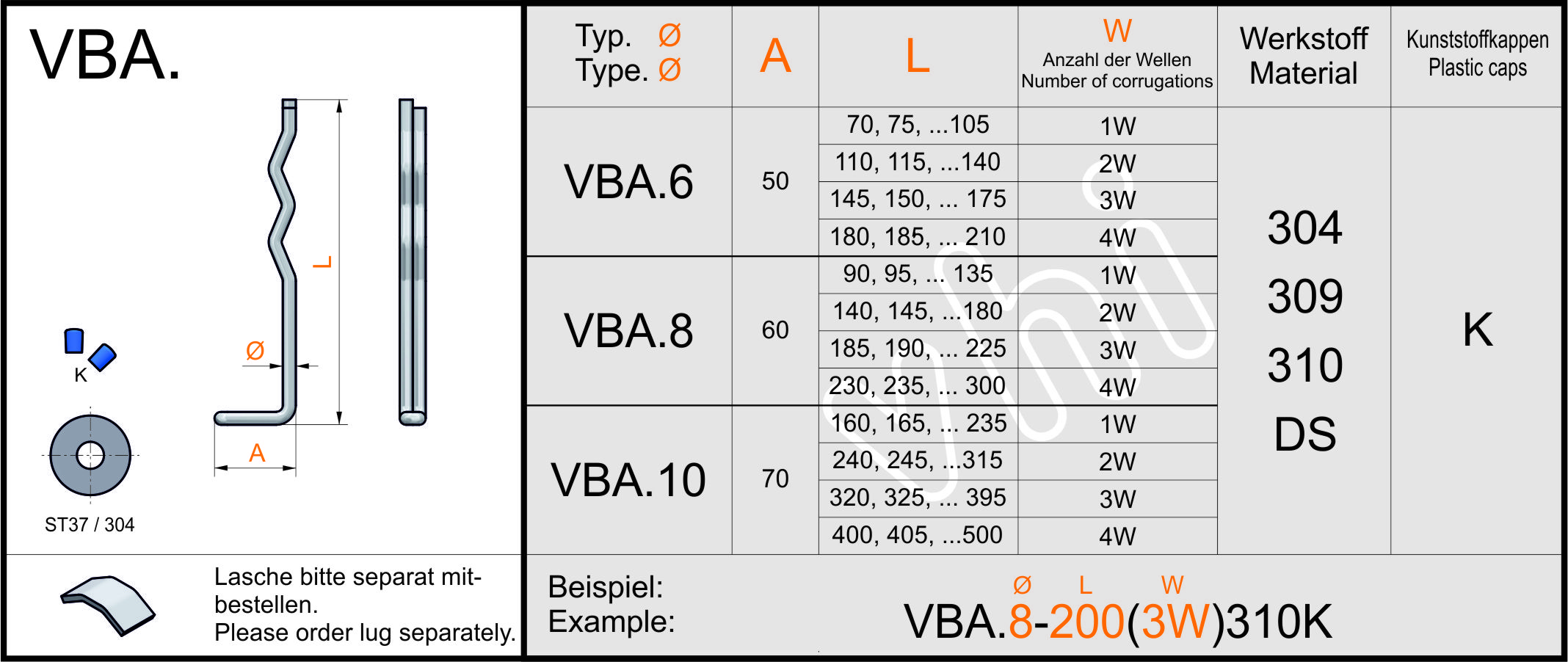

The VBA anchor system has been developed to ensure flexibility - for example in the case of end latches on the top edge of walls - in a vertical direction, something that is not the case with fixed systems. The VBA anchor is suspended in the previously welded lug. After the insulation has been installed it is bent onto the supplied disc, then the front layer made of cast or gunned concrete is inserted.

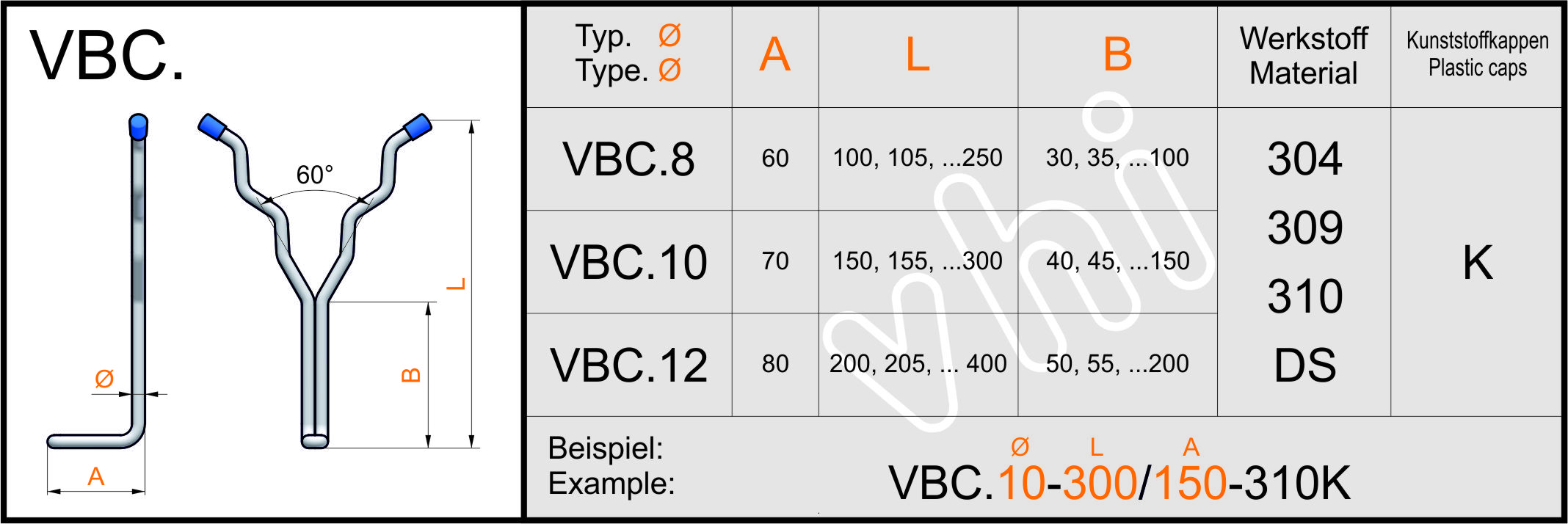

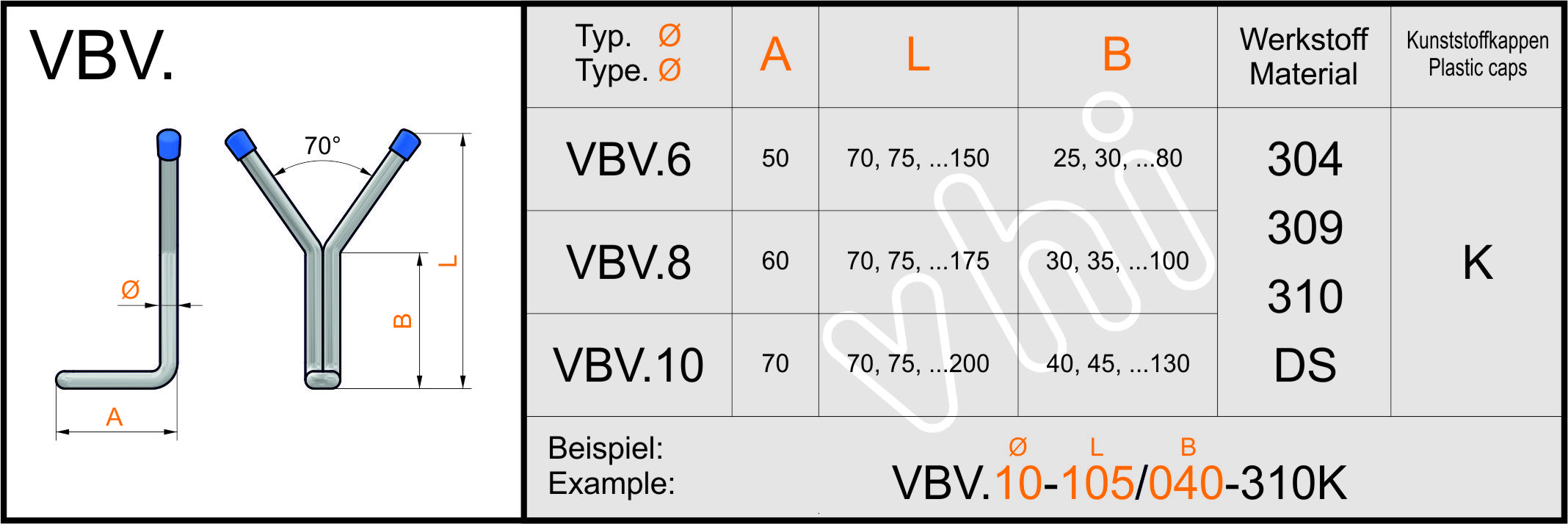

The VBV and VBC anchor systems have been specially developed for use with tamped linings. They are an alternative to the frequently used cast anchors. The anchors in the VBV and VBC Series consist of wrought alloy; the advantage of this is that the anchors do not break suddenly when they reach their limit load as cast anchors do, but adapt to the stress by expanding. These anchors are knocked halfway into the ramming mass as the lining progresses. The back end of the anchor is hung in a WH bracket. Unlike Type VBA, the corrugation of the VBC anchor is arranged horizontally to ensure a force-fit connection to the ramming mass.

Additional information

| APPLICATION | Side wall |

|---|---|

| ATTACHMENT | Manual welding |

| REFRACTORY LINING | Mixes |

| INSTALLATION | Aufbiegen, Einhängen, Einschlagen |

| POSITION | movable |

| TEMPERATURE | <1250°C |

| PROCESSING (CONCRETE) | Gießen, Spritzen, Stampfen |

| WALL CONSTRUCTION | Einschichtig, Mehrschichtig |