The fixing of anchors

The fixing point of a metal anchor is one of areas of the anchoring system subjected to the greatest load. In refractory installations the anchor system is mounted in different ways: in addition to welded connections, screw and plug-in connections are also used. The choice of kind of the mounting depends on the type of anchor, the alloy, the installing situation and not least on the amount of anchors to be implemented.

Two methods are deployed in the welding process that is predominantly used to mount anchors:

The manual welding with electrodes or wire (gas shielded arc welding)

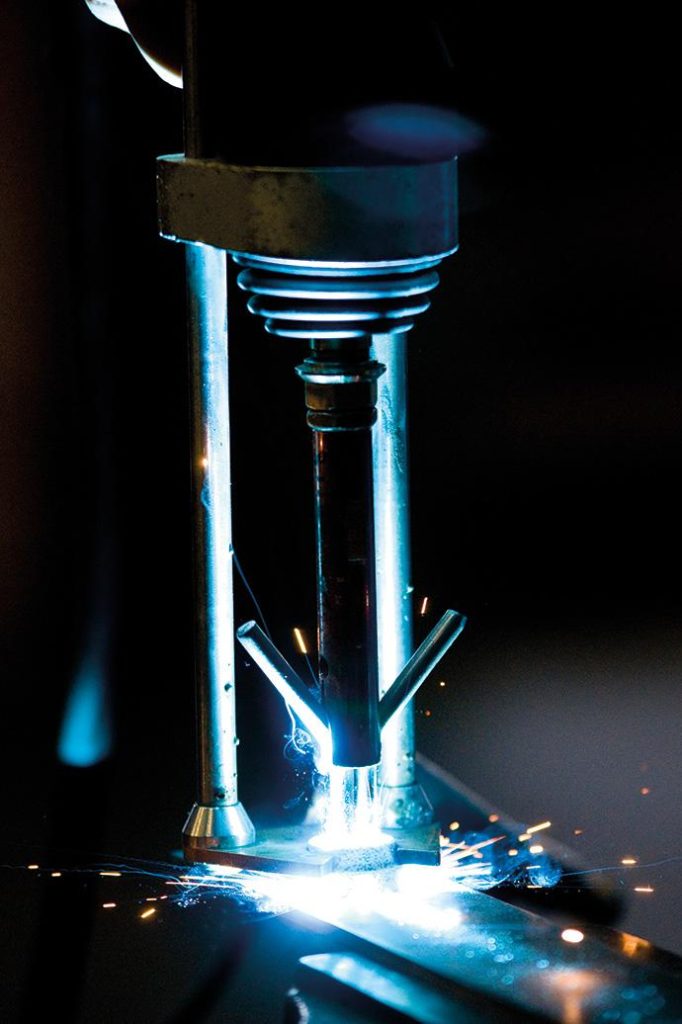

Part-mechanised welding with stud welding machines according to the drawn arc welding method.

Manual welding

Anchors are mainly manufactured from creep-resistant or heat-resistant alloys. The substructure, for example the wall of a component part, usually consists of carbon steel that is suitable for welding. This combination is referred to as a black and white connection. More rarely one comes across black/black or white/white connections. vhi supplies suitable electrodes for all these constellations.

Stud Welding

Stud welding, or more accurately stud welding with drawn arc, is an electric arc pressure welding method. In practice only stud welding with drawn arc and ceramic ferrule is used for refractory anchoring; this requires highly specialised welding machines. vhi supplies a series of robust, microprocessor-controlled stud welding machines that are simple to operate and guarantee high welding quality.