Why use round steel anchors?

About our anchoring system

Round bar anchors are the ideal anchoring solution

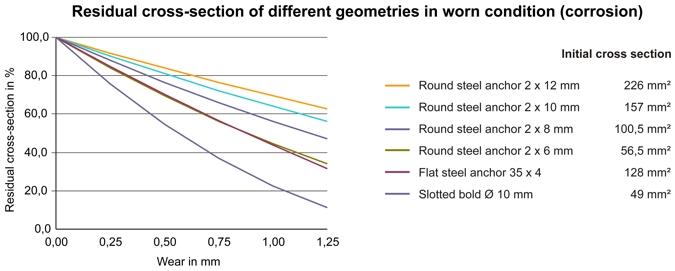

They have neither corners nor edges, and their relative surface is less than other cross-section shapes. Round bar anchors transmit retention forces evenly to the refractory concrete and have a smaller surface for corrosion attacks. Flat bar anchors have a number of disadvantages. The result of the square cross-section is that, due to its geometry, the anchor counters expansion in the refractory concrete in both main directions with very different resistance. This promotes crack formation emanating from the corners. Whilst flat bar anchors are usually manually welded, round bar anchors up to a diameter of 8 mm can be stud welded. Spraying shadows are likely to arise with gunned lining of refractory concrete using flat bar anchors, so that there are some areas in the refractory material with insufficient density.

The disadvantage of slotted pins is that their cross-section is seriously weakened at precisely the place where retention force is introduced to the refractory concrete. In the case of a pin with a diameter of 10 mm, the effective cross-section is reduced by almost 40 percent. Frequently the slot is not central, therefore in practice often leads to the thinner arm snapping. The slotted pin is very prone to corrosion because the relative surface on both arms is very large.

The alternative is the DS Series from vhi whose round bar anchors have the full cross-section over their entire lengths and which offer much less area for corrosion attacks due to their smaller surface.