vhi GmbH & vhi UK Ltd. – ikb GmbH | Andernach

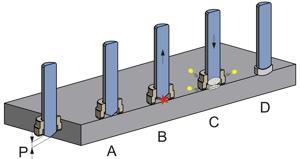

Before welding the anchoring element, the bolt or anchor, is pushed into the bolt holder and the ceramic ferrule is inserted in the ring holder. The tip of the welded part must stick out of the ceramic ring (Fig. P) by the length of the desired immersion depth. The welding gun is placed perpendicular on the item of work and pressed against it until the ceramic ring is sitting on thesurface of the item of work (Fig. A). The welding process is then initiated by pressing the trigger of the gun.

When the welding process is started:

Once the pre-defined time has expired, the microprocessor switches off the welding current and the gun lowers the anchoring element into the liquid metal which then cools and solidifies. This concludes the welding process, the ceramic ring is broken and removed (Fig. D); a visual check of the weld can then be made.