Prematerials

In the case of corrosion attacks, wire has an advantage compared to other cross-sections due to its geometry. However, depending on the processing stage of the wire, additional aspects are relevant to the selection of suitable primary material for metal anchoring.

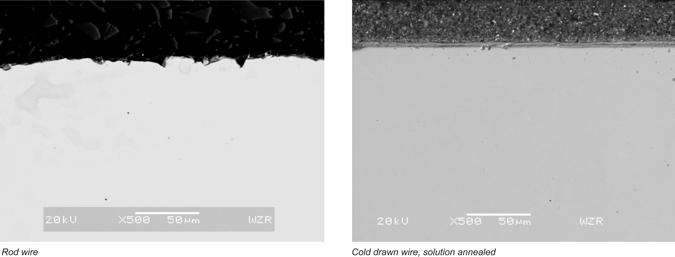

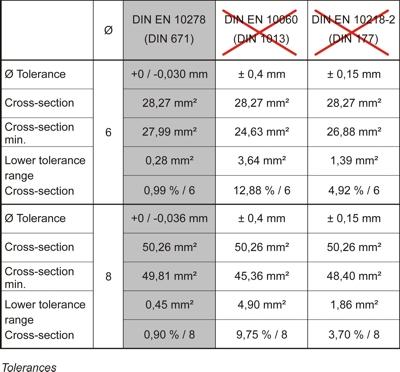

In the first processing stage, each wire is first produced as wire rod (DIN EN 10060, DIN 1013). The tolerances of the wire rod are relatively large (± 0.4 mm at ø 6 and 8 mm) and therefore a retention cross-section that is 10-12 % lower compared to the nominal dimension must generally be taken into account. The surface is rough which produces a larger relative surface and in turn leads to greater corrosion attack.

During production there is undefined cooling of the wire rod so that alloying components which, in the case of chrome/nickel alloys are essentially chrome, diffuse in the outer area of the wire. In this way the outer skin of the wire is enriched with chrome while the inner matrix has poorer amounts of chrome. This means that the inner area of the wire is more susceptible to corrosion. The outer areas with more chrome have a negative influence on welding capability, in particular in the case of stud welding. Wire rod should therefore where possible not be used to produce refractory metal anchors.

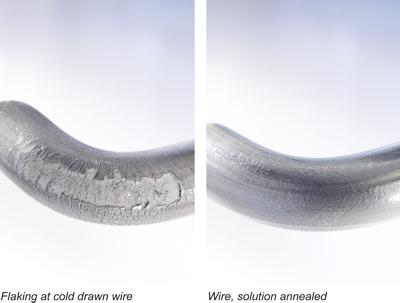

Drawn wire (DIN EN 10218-2, DIN 177), has less roughness and more favourable tolerances than wire rod. However due to the relative movement between the outer and inner area of the wire, a more or less strongly defined strain hardening ensues during drawing that has a negative influence on the heat and creep resistance of the material.

For this reason wire in this form should under no circumstances be used to manufacture metal anchoring systems. The ideal feed stock for metal anchoring systems is a wire that is solution annealed after the drawing process. As a result of solution annealing, the alloying constituent parts are distributed homogeneously, precipitations are dissolved, lattice imperfections eliminated and the grain size of the metal matrix adjusted.

Wire that passes through this production process is ideally suitable for use when manufacturing metal anchoring. For the production process using CNC-3D bending, the wires are calibrated to a very narrow tolerance (DIN EN 10278, DIN 671) to facilitate reproducible manufacture. Where possible the industrially manufactured wire is always produced at the lower tolerance limit. This means that the retention forces of the anchors made from the wire also only correspond to the weaker, lower tolerance.

For this reason vhi only uses wire that corresponds to standard tolerances (DIN EN 10278, DIN 671) and which has undergone the solution annealing process. We produce our anchoring systems by means of free bending on CNC-3D bending machines. As a result we ensure that a wire that meets our high quality requirements is also processed using a suitable method.

Massive forming, for example in a mould, can change the structure of the metal matrix. This can lead to substantial deformations in the wire (for example forming martensite), which can considerably reduce ductility. This is why we use the free bending method.